5/11(木)より着工した性能向上改修(長期優良住宅化リフォーム推進事業)「発寒の家Ⅲ」(ハッサムノイエⅢ)。最初の確認申請が昭和56年(1981年/新耐震)、平屋から2階増築のために行った二回目の確認申請が平成元年(1989年)。築42年の木造モルタル2階建てをマルっと「性能向上改修」します。今日は飛栄建設さんと建て主さん退去後、最初の現場打合せです。私の仕事は大工さんに床と壁の部分解体をしてもらって実態を確かめる事。理由は簡単で、この年代の確認図面は当てにならない場合も多いのと、住まい手さんが居る間は非破壊&目視が調査の限界だからです。検査の結果・・外装モルタルは当時一般的だった30~35mm厚ではなく20mm厚だったこと、下地のバラ板も厚18mmではなく12mmだったこと、内装ボードが9mmだった時代なので横胴縁が@455に施工されていること、1階根太は45×105(mm)なので大引きはピッチ@1820であることが分かりました。本日分かったことを加味して実施図面に修正を加えて行きます。

Construction began on May 11th (Thursday) for performance improvement renovations (long-term high-quality housing renovation promotion project) ``Cold House III'' (Hassam Noie III). The first application for confirmation was made in 1981 (New Earthquake Resistance), and the second application was made in 1989 for the purpose of adding a second floor from a one-story building. A 42-year-old wooden mortar two-story building will be completely renovated to improve its performance. Today is the first site meeting after Hiei Construction and the owner moved out. My job is to have the carpenter partially dismantle the floor and walls and check the actual situation. The reason is simple: confirmation drawings from this era are often unreliable, and non-destructive and visual inspection is the limit of investigation while the homeowner is present. The results of the inspection were that the exterior mortar was 20mm thick instead of the 30-35mm thickness that was common at the time, the underlying loose boards were 12mm thick instead of 18mm, and the interior board was 9mm thick, so the horizontal rim was constructed at @455, and the first floor joists are 45 x 105 (mm), so the pitch is @1820. We will take into account what we learned today and make corrections to the implementation drawings.

木造モルタル2階建て(元々は平屋)築42年をマルっと性能向上改修します。

The 42-year-old two-story wooden mortar building (originally a one-story building) has been completely renovated to improve its performance.

陸屋根を室内側から見上げたところ。本州の屋根が建物外周部に向けて勾配を取るのに対して、北海道の陸屋根の場合は勾配が逆。意外にも造りは似ていて@900の母屋に対して□45の垂木が@455、その上に12mmの野地板、ルーフィング、カラー鉄板の順。お約束なのは、屋根に載せた雪できんきんに冷やされた野地板に室内から逃げた湿気が触れてできた黒い結露痕。

Looking up at the flat roof from inside. While roofs in Honshu slope toward the outside of the building, flat roofs in Hokkaido have the opposite slope. Surprisingly, the construction is similar, with @455 having □45 rafters compared to the main building @900, followed by 12mm roofing boards, roofing, and colored iron plates, in that order. What you'll see is the black condensation marks left by moisture escaping from inside the room and coming into contact with the roof boards, which have been cooled by the snow on the roof.

竣工当初の風呂釜がFEタイプ(室内の空気を燃焼に使うタイプ)だったことが分かる痕跡。風呂釜が不完全燃焼しないように零下の外気を取り入れねばならなかった。現在一般的なFF式(燃焼には直接外気を燃焼部に導入する)に進化した理由がよく分かる。

Evidence shows that the bathtub was an FE type (a type that uses indoor air for combustion) when it was first built. To prevent incomplete combustion of the bath kettle, we had to draw in outside air at below zero temperatures. It is easy to see why it evolved to the currently common FF type (in which outside air is introduced directly into the combustion section for combustion).

室内側のグラスウールは比較的きれい。反対に屋外側は黒くなっている。理由は単純で・・内装のビニールクロスが結果的に防湿シートとして働いて壁内に湿気を入れなかったから。間柱は30×105(mm)@455、筋交いは45×90(mm)。モルタル下地のバラ板12mmとその隙間から黒く防水紙(アスファルトフェルド17kg/m3)が見える。

The glass wool on the indoor side is relatively clean. On the other hand, the outdoor side is black. The reason is simple...the vinyl cloth on the interior actually acts as a moisture-proof sheet and prevents moisture from entering the walls. Studs are 30 x 105 (mm) @455, braces are 45 x 90 (mm). The black waterproof paper (asphalt feld 17kg/m3) is visible through the gap between the 12mm loose boards on the mortar base.

湿気の入らなかった室内はあんなにきれいだったグラスウールの屋外側がこれ。室内側より、グラスウール、バラ板12mm、防水紙17kg/m3、ラスモルタル20mm

This is the outdoor side of the glass wool, which was so clean indoors with no humidity. From the indoor side: glass wool, loose board 12mm, waterproof paper 17kg/m3, lath mortar 20mm

こちらは中間仕切り。当時の内装ボードの主流が薄い9mmだったので、補強用に横胴縁18×45(mm)@455が標準。驚くべきことは・・柱と間柱の書き込みが現場施工であること。一本一本、鋸とノミで掘り込んでいる。今じゃあこの仕事はぜーんぶプレカットのルーター加工。新築ばかりの若い大工さんにはできませんよねえ~(笑)

This is the middle partition. At that time, the mainstream interior board was a thin 9mm, so the horizontal rim 18 x 45 (mm) @ 455 was standard for reinforcement. What is surprising is that the markings on the pillars and studs were done on-site. Each one is dug out with a saw and chisel. Nowadays, this job is all pre-cut router processing. A young carpenter who only builds new buildings can't do it (lol)

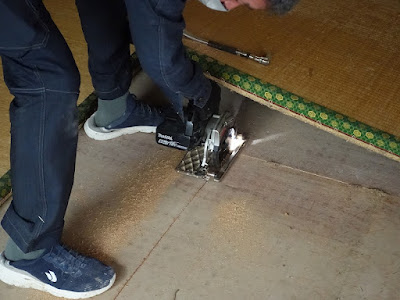

畳床を開口して床の構造を確認する。畳みの下はバラ板敷ではなくコンパネ(ラワン合板)が敷いてありました。

Open the tatami floor and check the structure of the floor. Under the tatami mats, there was a control panel (lauan plywood) rather than a wooden board.

素手で触るのは危険な40年前のグラスウール100mm(つーことは根太高さが105mm)。落下防止は根太間にトリカルネット

100mm glass wool made 40 years ago (the joist height is 105mm) which is dangerous to touch with bare hands. Trical net between the joists to prevent falls.

畳床を開口したところ。グラスウールの厚みが100mmあったにせよ、生グラスウールを直接床下の冷気に晒すとあまり効かない。もしトリカルネットの代わりに風を通さない透湿防水シートで覆ってあれば床の断熱は効く。今だからこそ言える事・・・

Opening the tatami floor. Even if the glass wool is 100mm thick, exposing raw glass wool directly to the cold air under the floor will not work very well. If the floor is covered with a breathable tarpaulin sheet instead of Trical Net, the floor insulation will be effective. I can only say this now...

防湿シートナシの床下。うっすらかび臭くもある。トリカルネットの下に見える二又菅は灯油のオイルライン(銅管)。防湿をして、床下地表面を断熱して、大引きを倍に増やす・・・

Under the floor without a moisture-proof sheet. There is also a slight musty smell. The forked tube visible under the trical net is a kerosene oil line (copper pipe). Moisture-proofing and insulating the subfloor surface will double the capacity...

今日はFIVW NEW OLD なんていかが

How about FIVW NEW OLD today?